At the beginning of the year, I promised you guys that I would write a book. After casting about for a subject, I finally decided to write about supported spindling--a topic that is often ignored or relegated to a footnote in most descriptions of hand spinning. It's coming along nicely. So far I have almost 200 text pages and suspect that after adding in all the images, the page count will balloon to 350 or so.

It will be first be published as an ebook PDF with embedded videos, all on a DVD. Those who wish printed copies will have to sign up for a subscription. It's a full-color book, and printing will be very expensive--about $30, plus the cost of the DVDs, shipping, and so on. A subscription with a down-payment will allow me to actually pay for the printing.

Right now, it looks like I will be finished with the text by the end of the year. Then it has to be tech-edited, copy-edited, laid out, proofed, and the videos created. I am aiming for publication somewhere between April and June.

In the meantime, I know that many readers don't spin, but half the book talks about various fibers. And so, here's is the first of several excerpts that I will be putting on this blog. All the images and spinning info have been removed here due to length considerations, but I hope you enjoy this brief tour of.....

Sunday, November 27, 2011

Eco-Junk

According to me (it's my book, after all), A Green Object is one in which the entire process, from start to finish, involves methodology safe to

living beings—plants or animals. Sustainability doesn't make something

Eco-Friendly, as anyone who has lived—and died young—near a paper mill could

tell you if they were still alive to give an opinion. Furthermore, biodegradablity

does not make something Eco-Friendly. Some nerve gas agents degrade naturally

after a few days, mammoth bones survive for thousands of years. Draw your own

conclusions.

With that definition in mind, let’s take a tour of

supposedly Eco-Friendly fibers.

Bamboo is frankly my least favorite fiber. Aside from its

lack of elasticity, it has an unpleasant scritchy feeling while being spun that

is reminiscent of squealing chalk-on-a-blackboard. It’s also an ecological

disaster. Like most rayons, bamboo is a regenerated cellulosic fiber. The most

common production method, called the Viscose Process, incorporates corrosive

chemicals such as carbon disulfide, sodium hydroxide and sulfuric acid. Aside

from the direct effects on workers, successful disposal of these chemicals

poses yet another set of knotty problems. And do think about the fact that most

of this stuff is made in countries that have a less enlightened view of worker

and environmental safety than we do.

A second method, the Lyocell process, is touted as being

more ecologically friendly. This process, which is also used to make Tencel®,

uses N-methylmorpholine-N-oxide (NMMO) as a solvent to dissolve the bamboo

cellulose into a viscose solution. This chemical is a hazardous irritant for

skin contact and has some corrosive potential, as well. Inhalation is not a

good idea either, as the chemical produces severe irritation of the respiratory

tract. Repeated or prolonged exposure can damage organs. And so on.

Finally, there is actually an eco-friendly enzymatic process

that produces a yarn known as bamboo

linen. It involves crushing the woody parts of the bamboo plant and using

natural enzymes to break the bamboo walls into a mush that can be mechanically

combed out and spun into yarn. This is essentially the same process used to

produce linen from flax and other bast fibers. Very little bamboo linen is

actually manufactured, because the process is very labor intensive and costly.

Bamboo is often touted as having antimicrobial properties.

Untreated bamboo fabric actually doesn’t have any such

effect, but inventing this feature makes for a good marketing. Go here to

read all about it.

Given all these factors, why has bamboo become a standard

addition to batts and tops? Well, it is shiny, and is thus considered a cheap

substitute for silk. There is no substitute for silk, whose glorious properties

I have already discussed.

Avoid it, and whine to battmeisters who toss the stuff into

a perfect good batch of merino.

Those who know me well also know how much I dislike tofu—a

squishy flavorless food with all the gustatory charm of wallpaper paste. I

spent years avoiding it in Japan,

and trust me, that’s like trying to avoid grits in North

Georgia. Come to think of it, grits rate about the same in my

culinary book.I do love

soybeans themselves, though. Delicious! Adorable!

Soybean fiber is made from tofu manufacturing leftovers.

Proteins are extracted from the residual oils, which is turned into a liquid

goo, cooked, wet-spun, stabilized by acetylating, curled, thermoformed, and cut

into three- to four-inch staple lengths. Several sites cheerfully describe the

process this way: “the soy protein is liquefied then extruded into fiber in a

chemical free process.”

Aside from having an abysmal understanding of punctuation,

the person who wrote this clearly slept through high school chemistry; acetylation

is a chemical process. A few of the non-chemicals used include acetic

anhydride, acetic acid, and sulfuric acid, the same chemical-free chemicals

that bamboo rayon manufacturers insist are Green!

We can skip over the acids, because everyone has a good idea

of what these do to animate and inanimate objects, so let’s investigate acetic

anhydride. According to the CDC’s NIOSH Pocket Guide to Chemical Hazards, exposure to this

stuff causes:

conjunctivitis,

lacrimation (discharge of tears), corneal edema, opacity, photophobia (abnormal

visual intolerance to light); nasal, pharyngeal irritation; cough, dyspnea

(breathing difficulty), bronchitis; skin burns, vesiculation, and sensitization

dermatitis

According to the eco-crap I

found on various sites, it supposedly possesses the softness of cashmere, and

has the moisture absorption of cotton with better diffusion, making it

“comfortable and sanitary.” In actual fact, it looks, feels, and spins just like bamboo rayon with the same annoying scritchy texture.

Sigh. Another Green Fiber made from a non-chemical chemical process.

This one was a toughie, because the vague description of the manufacturing

process made it difficult to figure out how it’s really manufactured. The

primary consumer fiber, Ingeo, is the trademark name for NatureWorks

LLC's synthetic fiber made from corn.

The site has a really pretty biocycle diagram showing

sunshine, corn plants, and some chemical marbles on sticks. Reading between the

lines and referring to some rather esoteric organic chemistry websites (But Ha!

I have a BS in Physical Chemistry), I tweezed out the following explanation: Corn

fiber is a bioplastic spun from lactic acid generated by bacterial fermentation

of corn sugars. That’s certainly sounds green.

Now we get to the good part: The lactic acid molecules link

together to form rings called lactic monomers, which, in turn, open and link

together to form long chains of polylactide polymers, which are then made into

a plastic. Notice they don’t tell you how this part is actually performed.

Next, I chased down polylactides--polyesters derived from

corn, sugarcane, and tapioca. Ah. Good old polyesters, which, among other

things, use concentrated sulfuric acid or dry hydrogen chloride gas for the

esterification process. BLAAAATTTT. Not Green.

The active ingredient of milk fiber is casein, a protein

that’s been around since ancient times. It’s been found on various ancient

Chinese and Egyptian artifacts and those who live in New England will be familiar with antiques coated in milk paint. Milk fiber was developed in the 1930’s and was

used as a wool substitute during WWII. It’s basically casein that has been

dissolved in an alkali bath, then processed in such a way that it can be blown

out of spinnerets—plates with zillions of tiny holes—where the liquid casein

then solidifies into fiber with the help of such friendly chemicals as strong

acids and formaldehyde.

After the war, the explosion of synthetics caused milk fiber

to fall out of favor. Thanks to the Eco-Junk movement, it’s experiencing a

minor renaissance. The newer process uses acrylonitrile, a human carcinogen,

which is bound to the casein, to produce a non-carcinogenic fiber. Among other

things, acrylonitrile is the primary ingredient of acrylic fiber, which will

not, under any circumstances, be discussed further in this book.

In any case, those who point to milk fiber as green and

eco-friendly should go take a good look at the eco-chemical properties of acrylonitrile and get

back to me.

So, milk fiber is sort of like rayon, which we have already

decided is liquefied plant goo shot through spinnerets. However, milk, being an

animal product, produces a fiber that dyes like wool and spins something like

silk.

Another fiber touted as eco-friendly and antibacterial,

chitosan is derived from shellfish carapaces and, oddly enough, mushrooms.

According to various websites, chitosan

has “scientifically proved biocompatibility,” and is “an absolutely safe

material.”

Chitosan itself is not useful to spinners, but let’s

look at Crabyon©, a blend of chitosan and

viscose, which should tip you off immediately about the chemicals used to

manufacture it. Refer to the Section on Bamboo for a complete

rundown of viscose rayon.

I am so sorry to disappoint seafood fans, but I was unable

to obtain a sample of this stuff. However, that won’t stop me from including it

in this section. I remember handling a skein of it a few years ago and thought

it felt like cotton with an odd squeaky texture.

I understand that people with shellfish allergies sometimes

have a reaction to the yarn, which makes it not “absolutely safe.” I

haven’t seen it around in a while, so perhaps the manufacturer rethought the

concept.

On the bright side, chitosan might fight fat, supposedly by

reducing lipid absorption, which means that if you manage to find crab fiber,

you can eat it and lose weight if you decide you don’t like to spin it.

Posted by

fleegle

at

2:07 PM

21

comments

![]()

Tuesday, November 15, 2011

A Long Story

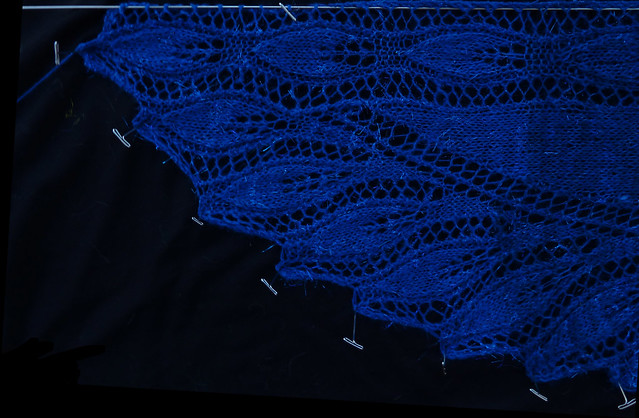

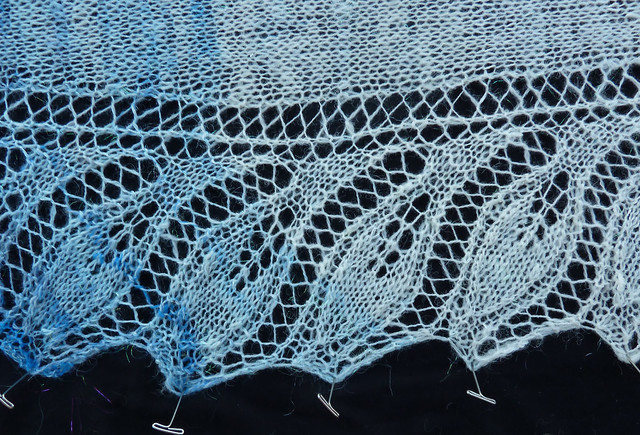

Semele is a terrific design for which I specially spun the yarn. I wanted the ends of the shawl to be dark blue, fading to white in the center, which is why the balls are wound the way they are. The lovely merino batts were made byLeilani Sue, and I bought the batts from her Etsy store, Heavenly Fiber. As you can see from the picture, I added plenty of Angelina for sparkle.

I heartily recommend the pattern, which had not a single error and left nothing to the imagination. It's worth knitting for the clever beginning leaf, from which the rest of the pattern flows without a hitch.

I was so careful after spinning. I measured and weighed the skein twice to be absolutely sure that I had two identical halves. But clearly Harry put his legs on the scale when my back was turned, because when I got to the last three leaves, I ran out of yarn.

I frantically emailed Leilani Sue, who was in the process of moving and thus had everything neatly packed in boxes. I whimpered. I whined. I sniffled. And dear Leilani Sue unpacked some boxes and found what she thought was the right color. Um, it wasn't. So I sent her a little sample of the spun yarn, and she unpacked more boxes and finally found a precious ounce of the dark blue.

So, after a month of squirming in anticipation, the merino arrived and I spun it up. The next day, Semele was finished and I gleefully started pinning it out. And pinning it out. And pinning it out some more...

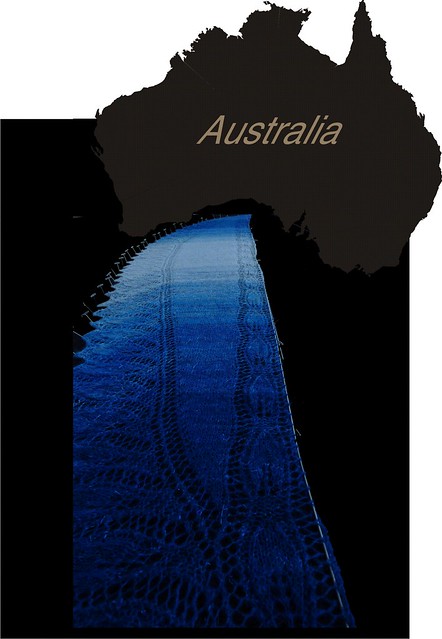

The length was my fault, because I kept knitting the center repeat until I had used up all the white, at which point the design faded back to blue. As I never bothered to measure it on the hoof, as it were, I got a long surprise when I blocked it.

Well, it will certainly wrap around me a whole lot of times...

Posted by

fleegle

at

5:31 PM

11

comments

![]()

Subscribe to:

Comments (Atom)